Can Carbon Fiber Stop a Bullet? Unveiling the Truth Behind Ballistic Resistance

The question of whether carbon fiber can stop a bullet is one that sparks considerable interest and debate, often fueled by its association with high-performance materials and futuristic technologies. While carbon fiber is undeniably strong and lightweight, its effectiveness as a ballistic material is more complex than it might initially seem. This comprehensive exploration delves into the capabilities and limitations of carbon fiber in stopping bullets, analyzing its properties, comparing it to other protective materials, and ultimately providing a clear, evidence-based answer.

This article aims to provide a definitive answer, explaining the science behind carbon fiber’s interaction with projectiles, exploring different weaves and composite structures, and examining real-world applications where carbon fiber offers ballistic protection. We will also address common misconceptions and provide a balanced perspective on the material’s potential and shortcomings. Prepare to discover the truth behind carbon fiber’s ballistic capabilities.

Understanding Carbon Fiber: Strength and Structure

Carbon fiber is a polymer, sometimes known as graphite fiber, and is a material consisting of thin, strong crystalline filaments of carbon that are used to strengthen materials. These fibers are incredibly strong for their weight, making them ideal for applications where high strength-to-weight ratios are crucial, such as aerospace, automotive, and sports equipment. However, the way carbon fiber is manufactured and how it’s implemented into a product is key to understanding its strength and the ability to stop bullets.

The strength of carbon fiber comes from its unique structure. The carbon atoms are bonded together in long chains, aligned parallel to the fiber’s axis. This alignment gives the fiber exceptional tensile strength, meaning it can withstand significant pulling forces. However, carbon fiber is less resistant to compressive forces (forces that try to crush it) and impact forces (sudden, high-energy impacts).

The Role of Resin and Weave Patterns

Carbon fiber is rarely used in its raw fiber form. Instead, it’s typically combined with a resin matrix to create a composite material. The resin binds the fibers together, distributes the load, and protects the fibers from environmental damage. The type of resin used and the way the carbon fibers are arranged (the weave pattern) significantly affect the composite’s overall strength and impact resistance.

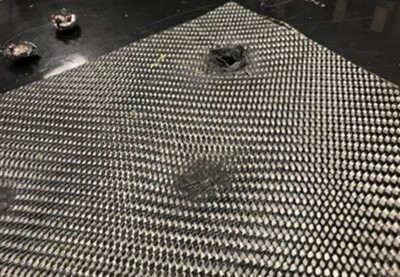

Common weave patterns include plain weave, twill weave, and satin weave. Each weave offers a different balance of strength, flexibility, and aesthetic appeal. For ballistic applications, specific weave patterns and resin formulations are chosen to optimize energy absorption and minimize penetration.

The Science of Ballistic Resistance: How Materials Stop Bullets

To understand whether carbon fiber can stop a bullet, it’s essential to understand the science of ballistic resistance. When a bullet strikes a material, it transfers kinetic energy to the material. The material’s ability to stop the bullet depends on its capacity to absorb or dissipate this energy.

Different materials employ different mechanisms to stop bullets. Hard materials, like steel, resist penetration by deforming the bullet or causing it to fragment. Soft materials, like Kevlar, absorb energy by stretching and deforming, spreading the impact over a larger area.

Energy Absorption Mechanisms in Composites

Composite materials, including carbon fiber composites, combine these mechanisms. When a bullet strikes a carbon fiber composite, the fibers resist penetration, while the resin matrix helps to distribute the impact energy. The fibers may break, but they do so in a controlled manner, absorbing energy in the process. The resin can also deform and crack, further contributing to energy absorption.

The key to effective ballistic resistance is to maximize energy absorption while minimizing penetration depth. This requires careful selection of materials, weave patterns, and resin formulations.

Carbon Fiber vs. Traditional Ballistic Materials: A Comparative Analysis

Carbon fiber is often compared to other ballistic materials, such as steel, Kevlar, and ceramic composites. Each material has its own strengths and weaknesses in terms of weight, strength, cost, and performance.

- Steel: Offers high ballistic resistance but is very heavy.

- Kevlar: Lightweight and flexible but less effective against high-velocity projectiles.

- Ceramic Composites: Very hard and resistant to penetration but brittle and expensive.

Carbon fiber offers a good balance of weight and strength, making it attractive for applications where weight is a concern. However, its ballistic resistance is generally lower than that of steel or ceramic composites. According to materials engineers, the specific arrangement and type of weave significantly impact the effectiveness of carbon fiber in stopping bullets.

The Role of Material Thickness and Layering

The thickness of the material and the number of layers used also play a crucial role in ballistic resistance. Thicker materials and multiple layers provide more opportunities for energy absorption and reduce the likelihood of penetration. Carbon fiber composites can be layered to achieve the desired level of protection, but this adds weight and cost.

Real-World Applications of Carbon Fiber in Ballistic Protection

While carbon fiber’s primary use isn’t as a standalone bulletproof material, it has found niche applications in ballistic protection where weight is a critical factor. These include:

- Vehicle Armor: Carbon fiber composites are used to reinforce vehicle armor, reducing weight while maintaining a reasonable level of protection.

- Helmets: Carbon fiber is used in some helmets to provide impact protection, though it’s often combined with other materials for ballistic resistance.

- Body Armor Inserts: Carbon fiber can be used as a component in body armor inserts, providing additional protection against specific threats.

In these applications, carbon fiber is typically used in conjunction with other materials, such as ceramics or high-strength polymers, to provide a layered defense against ballistic threats. This hybrid approach leverages the strengths of each material to achieve the desired level of protection.

Factors Affecting Carbon Fiber’s Ballistic Performance

Several factors can affect the ballistic performance of carbon fiber composites, including:

- Fiber Type: Different types of carbon fiber have different strengths and stiffnesses. High-strength carbon fibers generally offer better ballistic resistance.

- Resin Type: The type of resin used can significantly affect the composite’s impact resistance and energy absorption capabilities.

- Weave Pattern: The weave pattern affects the way the fibers distribute the load and resist penetration.

- Manufacturing Process: The manufacturing process can affect the quality and consistency of the composite, which can impact its ballistic performance.

- Projectile Type: The type of bullet or projectile being fired can also affect the material’s performance.

Careful consideration of these factors is essential when designing carbon fiber composites for ballistic protection applications.

Testing and Certification Standards for Ballistic Materials

Ballistic materials are subject to rigorous testing and certification standards to ensure their effectiveness. These standards specify the types of projectiles that the material must be able to stop and the level of protection it must provide.

Common testing standards include:

- NIJ Standard 0101.06: The U.S. National Institute of Justice standard for body armor.

- MIL-STD-662F: The U.S. military standard for ballistic testing.

- VPAM: European standard for ballistic testing.

These standards define the testing protocols, including the types of firearms and ammunition used, the impact velocities, and the acceptance criteria. Materials that meet these standards are certified as providing a specific level of ballistic protection.

Debunking Myths and Misconceptions About Carbon Fiber and Ballistics

There are many myths and misconceptions surrounding carbon fiber and its ballistic capabilities. One common myth is that all carbon fiber is bulletproof. This is simply not true. While carbon fiber composites can provide some level of ballistic protection, they are not inherently bulletproof. The level of protection depends on the factors discussed above, such as fiber type, resin type, weave pattern, and manufacturing process.

Another misconception is that carbon fiber is always superior to other ballistic materials. In reality, each material has its own strengths and weaknesses, and the best choice depends on the specific application and requirements. Carbon fiber is not a magical material that can solve all ballistic protection challenges.

The Future of Carbon Fiber in Ballistic Protection

The future of carbon fiber in ballistic protection looks promising, with ongoing research and development efforts focused on improving its performance and expanding its applications. Advances in fiber technology, resin chemistry, and manufacturing processes are leading to stronger, lighter, and more impact-resistant carbon fiber composites.

One promising area of research is the development of new weave patterns and composite structures that can better absorb and dissipate impact energy. Another area of focus is the incorporation of nanoparticles and other additives into the resin matrix to enhance its properties. These innovations could lead to carbon fiber composites that offer significantly improved ballistic protection.

Is Carbon Fiber Right for Ballistic Protection? Weighing the Pros and Cons

In conclusion, while carbon fiber can stop a bullet under certain circumstances, it’s crucial to understand its limitations and compare it to other ballistic materials. Carbon fiber is not a universal solution for ballistic protection, but it can be a valuable component in specific applications where weight is a critical factor.

Pros:

- Lightweight

- High strength-to-weight ratio

- Can be tailored to specific applications

Cons:

- Generally lower ballistic resistance than steel or ceramic composites

- Can be expensive

- Performance depends on multiple factors

Ultimately, the decision of whether to use carbon fiber for ballistic protection depends on a careful evaluation of the specific requirements and constraints of the application. If you are considering using carbon fiber for ballistic protection, it’s essential to consult with experts in materials science and ballistic engineering to ensure that you select the right materials and design for your needs. Share your thoughts and experiences with carbon fiber and ballistic protection in the comments below.